4MWh/day Solar power plant

Per NASA's Solar Power Technologies for Future Planetary Science Missions

Advances in solar array performance are envisioned: a) near-term: 150–200 W/kg, b) mid- to far term: 200–250 W/kg.

And https://www.nasa.gov/smallsat-institute/sst-soa/power

Flexible and thin-film solar cells have an extremely thin layer of photovoltaic material placed on a substrate of glass or plastic. Traditional photovoltaic layers are around 350 microns thick, while thin-film solar cells use layers just one micron thick. This allows the cells to be flexible and lightweight and, because they use less raw material, are cheap to manufacture. In 2014, FirstSolar announced a flexible solar cell design with an efficiency of 20.4%, closing the gap on single-junction solar cells. Flexible solar cells designed specifically for space applications are available from United Solar and have an efficiency of 8% (in 2014) on 1 mil polymer giving them a specific power of 750-1100 Wkg-1.

Thus ..............

So say 1000 W/kg = 1KW/kg = 1 MW/1000 kg = 1 MW/MT = 100 MW/Starship ... on a 1 mil polymer.

So I imagine large 10 m x 100 m rolls of this inside a Starship (1,000 m^2 each) - about football field size

Say this can be packed so this is effectively 2-3 mil thick ... this creates a footprint in the cargo bay (in landed vertical orientation) of 2m x 2m = 4 m^2. Given that the bay has 50 m^2 of floorspace lets assume that packing will allow for 40 m^2 of space ... so it can easily carry 10 10 m x 100 m rolls ... maybe 15 with more optimal packing.

So at least 10,000 m^2 of these thin solar arrays can be packed in a Starship, maybe 15,000 m^2.

To figure out the mass per kg of these thin solar arrays ... if you get 8% efficiency (as stated above) you get 60W per m^2 on earth ... and the material provides about 1000W/kg

So that material is 0.06 kg/m^2 -> 6,000 kg per 10,000 m^2 (packed Starship bay)

Clearly Starship is volume vs mass constrained ... this material could be 2-3 times more dense and there should be no problem in launching it and working with it. Rollers, deployers and other needed equipment could add another 10-20 mT for this Mars Solar Powerplant.

Finally ...

The solar flux onto a 30 deg tilted solar collector at 40 deg on Mars is at least 200W/m^2 over a 10 hours a day

If you get 20% efficiency (I assume the 8% will be 20% in 2024) its 40W/m^2

So an average of 400Wh/m^2 day per on Mars at mid-latitude, assuming no dust issues.

At 10,000 m^2 you have 4MWh per day ... At 15,000 m^2 you have 6MWh per day ...

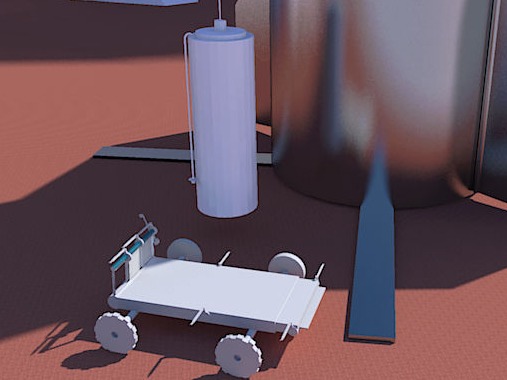

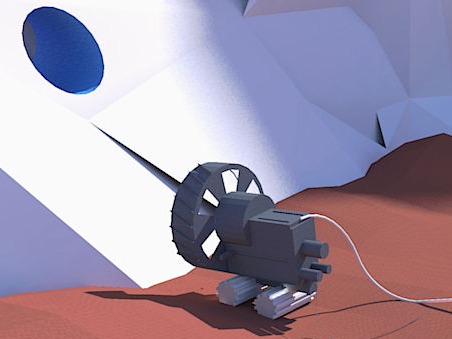

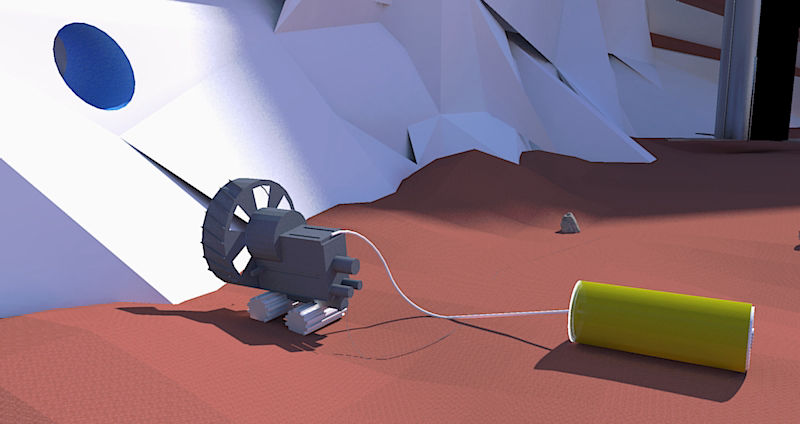

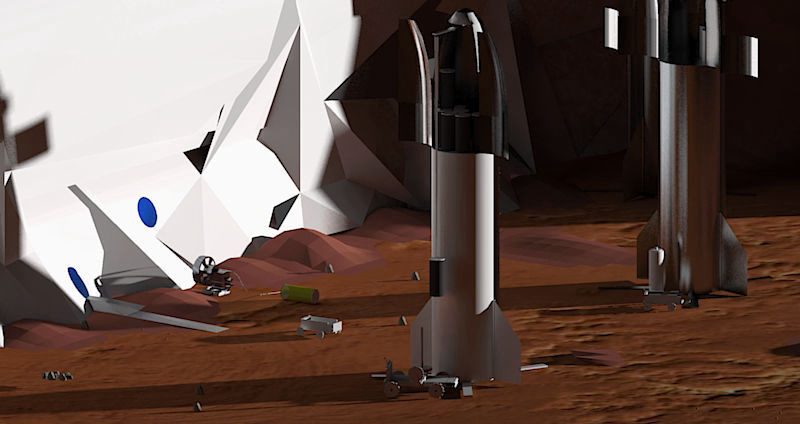

For deployment one would need a "laydown" machine (LM) to accept rolls from the Starship and take them to a hillside pointed in the right direction, and roll them out. Proximity of a hillside might be part of the base site criteria. The LM would need to also lay cable and connect them up. Small NASA heli-drones would come by and blow dust off if needed. We might go with 5m high rolls instead to reduce the size of the LM.

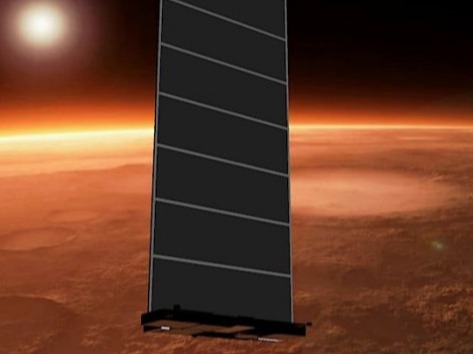

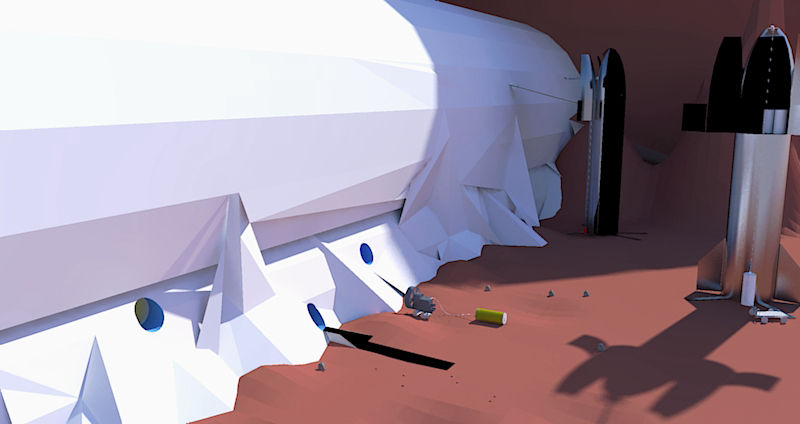

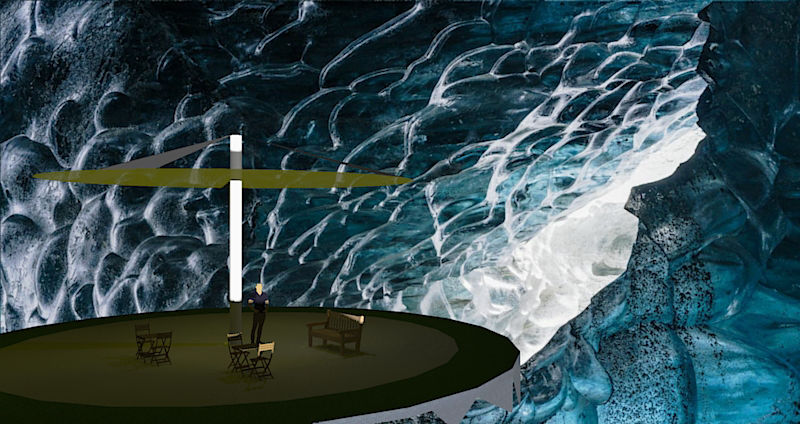

Below is render of a Starship bringing in those 5m rolls and lowering them down to a waiting LM: