Why the first Mars power grids will be Low Voltage Direct Current (LVDC):

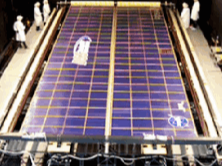

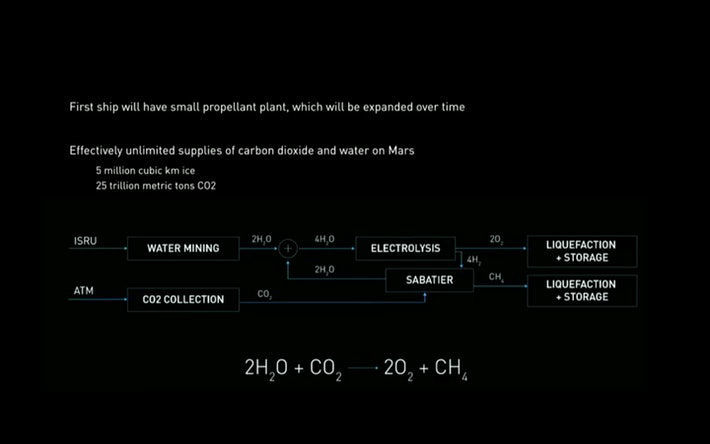

1) Mars power will be primarily multi-MW scale solar (DC) buffered by lithium-ion batteries (DC). There may be a backup MethLOX generator (fueled by stored MethLOX from the MethLOX factory) for long dust storms which will be AC. That AC -> DC conversion will likely be no more 93% efficient.

2) As a Mars colony distribution grid will likely be within a 3 - 4 km radius circle, AC's advantage of long distance transmission does not apply.

3) DC power cabling is more mass efficient than AC with Heavy Duty AWG 4: 0.2 kg/m, 200 kg/km. The power distribution system cables mass may be as low as 2 mT.

4) If needed, DC -> AC (97% efficient) conversion is more energy efficient than AC -> DC (87-93% efficient). Changes in DC voltage are very efficient at 99% (and the equipment does not appear to be large or heavy).

5) While DC -> DC power conversion equipment is more expensive per KW than AC -> AC, that price different won't be significant in the cost of a Mars colony. DC -> AC Inverters will be needed in edge equipment that does not have a good DC alternative, and at the MethLOX Factory to convert AC -> DC for emergency backup power during long dust storms (of durations that exceed the the capacity of the distributed battery network).

6) Using Tesla Powerpack 2 4HR (used in Power Grid application, Capacity: 210 kWh, Op Temp: −30 to 50 °C, Mass: 2,160 kg, Size: 218.5 cm × 82.2 cm × 130.8 cm provides 960 VDC 66 A 55 kW) the 2 mT battery mass looks like the main limitation. Assume 2100 kWh ... so 10 of these (20 mT total) distributed around colony. Note that batteries may be based placed within areas that are human occupied since the operation temperature is only as low as -30C, which is much higher that average Mars surface conditions.

7) It exists now: LVDC has already been adopted as a medium of distribution in many applications such as data centers and telecommunication power systems.* With the rise of residential solar power DC is becoming the most efficient choice even for the mixed DC/AC home.

8) More standards are emerging and lower cost equipment to meet them. Emerge Alliance, together with the partnership between Japan and South Korea’s governments, with academic institutes, and industrial groups, have also made a significant development on the standardization and technological development of DC-powered buildings and microgrids. So far, the standards for using DC with AC in hybrid settings in commercial buildings are established by the Emerge Alliance, which uses 48 V DC for low-power applications and 380 V DC for high power applications.* Note that 48 V, 220 V, and 380 V DC are the default voltage choices.

References:

* DC distribution for residential power networks—A framework to analyze the impact of voltage levels on energy efficiency: https://www.sciencedirect.com/science/article/pii/S2352484719313757

Why DC cable is better than AC: https://www.zmscable.com/new/The-difference-between-DC-cable-and-AC-cable-in-power-cable